■ Compact in size with high degree of automation, Human machine interface, simple to operate.

■ Touching screen with bilingual languages display: Chinese & English selectable.

■ Standard machine with one shuttle table and one punching head, it could be customized to be a Dual Shuttles & Dual Heads based production UPH requirement.

■ Equipped safety light curtains at the entrance, protect Human safety.

■ It’s able to connect and cooperate with a Picking & Placing robot instead of operator to placing & taking off the board from Die fixture, saving H/Cs.

■ The Die fixture is made from special steel, with high precision and long life-span.

■ Max. 10 Tons punching force minimized mechanical stress on SMT components during work and avoiding making creaks on solder joints and broken the sensitive components.

■ Standard machine is designed with servo motor; Hydraulic solution is negotiable.

■ CE is optional.

If you are interested in our products, please email to Sales@jinke-tech.com

If you are interested in our products, please email to Sales@jinke-tech.com

|

Model |

JK-D-10TSSS |

JK-D-10TSDD |

JK-S-10TSSS |

JK-S-10TSDD |

|

Machine style |

Desktop |

Desktop |

Standalone |

Standalone |

|

Controlling system |

HMI+PLC |

HMI+PLC |

HMI+PLC |

HMI+PLC |

|

Display |

Touch-panel |

Touch-panel |

Touch-panel |

Touch-panel |

|

Languages |

Chinese/English |

Chinese/English |

Chinese/English |

Chinese/English |

|

Max. force |

10tons |

10tons |

10tons |

10tons |

|

Force generator |

Servo motor |

Servo motor |

Servo motor |

Servo motor |

|

Shuttle table |

Single |

Dual |

Single |

Dual |

|

Punching head stroke |

80mm |

80mm |

80mm |

80mm |

|

Accuracy |

+/-0.05mm |

+/-0.05mm |

+/-0.05mm |

+/-0.05mm |

|

Working area |

std350x250mm |

std350x250mm |

std350x250mm |

std350x250mm |

|

Punching head No. |

Single |

Dual |

Single |

Dual |

|

Power Supply |

AV200-240V 50/60HZ |

AV200-240V 50/60HZ |

AV200-240V 50/60HZ |

AV200-240V 50/60HZ |

|

Connected power |

300W |

500W |

300W |

500W |

|

Net Weight |

300Kg |

500Kg |

400Kg |

600Kg |

|

Footprint (LWxH mm) |

600x700x1250 |

1000x700x1250 |

600x700x1450 |

1000x700x1450 |

|

Model |

JK-D-10TSSS |

JK-D-10TSDD |

JK-S-10TSSS |

JK-S-10TSDD |

|

Machine style |

Desktop |

Desktop |

Standalone |

Standalone |

|

Controlling system |

HMI+PLC |

HMI+PLC |

HMI+PLC |

HMI+PLC |

|

Display |

Touch-panel |

Touch-panel |

Touch-panel |

Touch-panel |

|

Languages |

Chinese/English |

Chinese/English |

Chinese/English |

Chinese/English |

|

Max. force |

10tons |

10tons |

10tons |

10tons |

|

Force generator |

Servo motor |

Servo motor |

Servo motor |

Servo motor |

|

Shuttle table |

Single |

Dual |

Single |

Dual |

|

Punching head stroke |

80mm |

80mm |

80mm |

80mm |

|

Accuracy |

+/-0.05mm |

+/-0.05mm |

+/-0.05mm |

+/-0.05mm |

|

Working area |

std350x250mm |

std350x250mm |

std350x250mm |

std350x250mm |

|

Punching head No. |

Single |

Dual |

Single |

Dual |

|

Power Supply |

AV200-240V 50/60HZ |

AV200-240V 50/60HZ |

AV200-240V 50/60HZ |

AV200-240V 50/60HZ |

|

Connected power |

300W |

500W |

300W |

500W |

|

Net Weight |

300Kg |

500Kg |

400Kg |

600Kg |

|

Footprint (LWxH mm) |

600x700x1250 |

1000x700x1250 |

600x700x1450 |

1000x700x1450 |

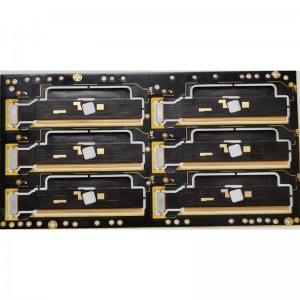

■ Product samples

■ CAD drawing

■ PCB Gerber (no need inner layers)

■ 3D drawing

■ Production process requirements